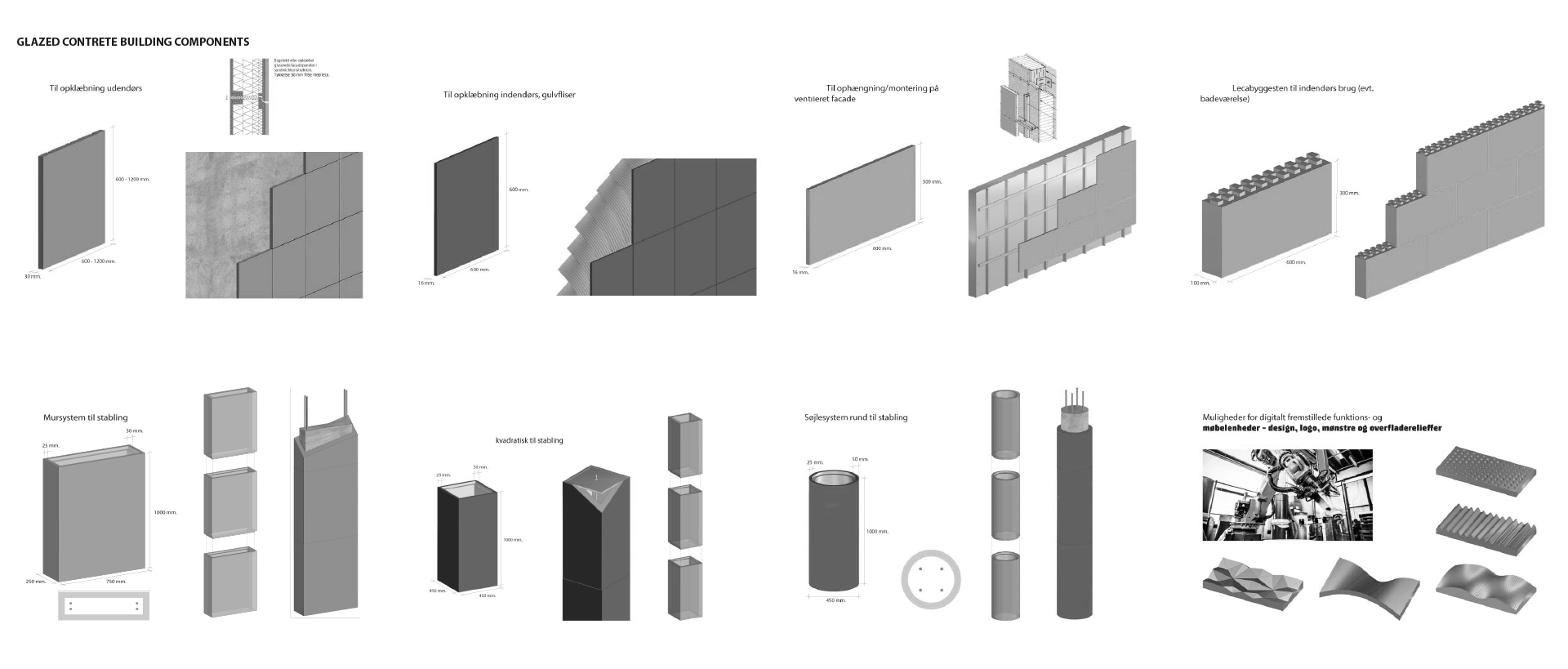

GLAZED CONCRETE BUILDING COMPONENTS

- From 1/5-1/11/2011 wrote a Prædoc. “Glazed lightweight building components” from the Centre for Design Research at the Royal Academy School of Architecture, attached to Institute 4/advisers Anders Brix & Anders Abraham.

- In 2013, received a grant from Aase and Ejnar Danielsen‘s Foundation to further develop the project.

- In 2014, received a grant from Merchant LF Foght‘s Foundation.

- In 2014, started collaboration with the Danish Technological Institute to complete the project. Received a grant from the National Research and Innovation Agency.

- 2017 -2019 grant from Research and Innovation Fondation, Otto Bruuns Fondation and Realdania.

- 2019 – 2021 Mock- up / reference wall grant from Realdania

The goal of the project is to optimise and commercialise a new groundbreaking construction product, glazed concrete construction components, and to identify and fill a knowledge gap in the new material technology. The goal is to develop the aesthetic potential of concrete, as well as to identify possible technical challenges/issues by identifying this type of upscaling of facade panels. Large scale glazed concrete surfaces could have a significant bearing on the building’s visual expression with beautiful colour and texture expression, in that it would create an alternative to, for example, divided tile and brick facades. The glazed surfaces are also very durable, wear-resistant and weatherproof.

Why glazed concrete? Large scale glaze treated concrete formwork would run along the entire stretch of the element and would not be divided into bricks, tiles, plaques and grouting as it usually is. In other words, it will form larger elements and thereby affect the visual expression.

This development project will help to develop new concrete aesthetics and put it in a contemporary context.

The idea

The glazed concrete building components modular construction system of 3 cm thick glazed concrete slabs in different geometries and sizes combines the tile’s beautiful surface and durability with lightweight low cost, shape stability, flexible formats. They have clear colors, are durable, weatherproof, without steel fibers, no flare in the glaze, a lower burning temperature and can be scaled up to large formats.

The glazed concrete building components panels are an alternative to ceramic tile & brick’s divided facades. Gives buildings and spaces new visual design concepts and features including . Can tie inner and outer surfaces together with functional fixtures and unclean furniture. Can be used as an in situ molded column / wall element, recessed in the production environment as an integrated wall / fixture element or cladding facade panels.

The goal is, among other things, to test the concrete composite within 3D print / building elements / fixtures, uban designs / furniture.

The target group is architects, builders, contractors and construction markets – dk who are constantly looking for technologies for new designs inside as well.

The product has news value and substitutes painted steel plates, bricks, ceramic tiles, glass and foreign glassware. Dyed glass is durable, heavy, fragile and expensive, tiles have limited possibility of upscaling.

NEWS VALUE

DURABLE

HIGH STRENGTH

COLOR WEIGHT (DOES NOT SHELL)

AESTHETIC SUBSTANTIVE EXPRESSION

LARGE FORMATS (Large formats can only be produced in this special concrete, which tiles cannot, as it cracks. Architects demand glazed large format panels / tiles).

LONG-TERM DURABLE

WEATHER RESISTANT

CLEANING FRIENDLY

EXCLUSIVE MATERIAL

FACTS

Weight 1x1mx16mm = 42 kg

Shrink approx. 0.01%

The load-bearing capacity of the tiles when suspended from facades will have a load-bearing capacity far above what is necessary

Bending strength 16 mm tile = 15.0 MPa

Bending strength Leca building blocks 100 mm = 1.8 MPa

Compressive strength = 10,888 MPa

Scratch test / Mohs hardness Apatite = 5, Feldspar = 6, Quartz = 7, Topaz = 8, Corundum = 9

Adhesion of tiles Technique Bottering Floating).

Ideal for suspended facade / ventilated facade.

Ongoing Mock-up wall /reference wall

In collaboration with an arhitectural firm supported by Realdania